357th FG Profile

Lt. Col Andrew Evans, last Commanding Officer of the 357th FG, 6 Victories.

Spring, 1945

Modeler Tips:

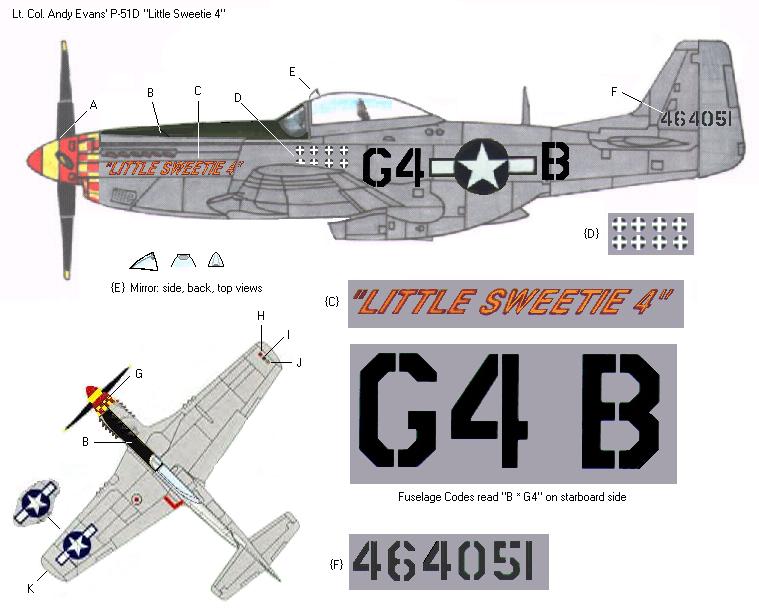

Side View Notes:

A. Rear red band on propeller boss extends onto spinner to leading edge of blades when in

neutral pitch. Determine width of yellow band by dividing remainder of spinner evenly.

B. “Little Sweetie 4” in deep yellow with a red border, placed with top edges of lettering on upper seam of lower strip panel and the number “4” slightly overlapping the firewall seam.

C. Glare shield is flat black and tapers away from upper cowl seam toward center of aircraft

from forward bulkhead to propeller boss.

D. Victory Board. 8 white crosses within black circle, 4 columns of two. Top row adjacent to panel seam.

First column lines up directly beneath lowest point of side windscreen.

E. Clear perspex quarter dome with oval mirror placed inside apex. Not standard equipment, can be

made from scratch using Squadron Brand “Heat & Smash” Canopy Film. I used sandpaper to even up the shape of the front corner of an extra Spitfire Mk V “clipped wingtip” from my surplus parts as a smash mold. Refer to photo of P-51D on Modeler’s Guide front page.

F. There were no antenna wires installed on this aircraft. Tail Number- black “464” on fin, yellow “051” on rudder.

Upper & Lower View Notes:

G. Width of checkers reduced on underside in order to fit evenly on the narrow surfaces of the chin scoop area. H, I, J. Red, Green, Yellow navigation lights- circular and flush with wing panel.

K. Formation Lights- Red (Port) and Green (Starboard)

Overall Modeling Tips:

*Paint on the flat colored glare shield first- then mask it off and paint the remainder of the aircraft in natural aluminum color. Most metal colors will be marred or removed by masking materials and should therefore be

applied last. Note that this aircraft did not wear any recognition stripes, after the New Year 1945, most Mustangs in the ETO adopted a cleaner appearance by omitting theatre markings.

*After building several 357th A/C over the past 30 years, I recommend painting the nose area forward of the exhaust cutout yellow when the flat features are painted. Then when decal time comes, carefully cut away the

yellow squares from the checkerboard decal and apply the remaining strip of red checkers to the nose. This method significantly reduces the potential for bubbles, and wrinkles plus it makes exact alignment of the decal easier.

*Prior to assembly, wash clear plastic parts with a mild glass cleaner and gently wipe dry. Then use a Q-Tip to evenly spread clear liquid floor wax (Future Brand seems to get the best results) on both inside & outside.

Protect from dust and let dry for at least 2 hours. The wax fills in microscopic flaws and creates an even gloss that is clearer & shines brighter than the original plastic underneath.

Lt. Col. Andy Evan’s P-51D Mustang “Little Sweetie 4”